The Company

MEKEL was founded in 2008 and executes technical projects in the Environmental field in Cyprus and the abroad. Well within its second decade of existence, MEKEL already has a solid track record of over one hundred successfully completed infrastructure projects in the Private and Public Sectors.

Our Team consists of highly skilled personnel (Engineering, Technical, Managerial and Supportive) with decades of applied experience that allow MEKEL’s different departments (Design, Procurement, Tendering, Operation, Maintenance, Quality & Management) to deliver excellent results. MEKEL diligently invests in People Development as it is the backbone of our Success.

MEKEL, being a leading player in Cyprus, offers comprehensive (Design, Build & Operate) and Sustainable Solutions at a time when the implementation of projects for the protection of the Environment becomes more and more eminent.

MEKEL’s projects always take into account our Client’s Capital and Operational limitations while obeying the Legal framework.

Waste Water Treatment

In water and wastewater treatment applications, the highest possible degree of purification is required when it comes to water recycling and reuse. Recycled water can satisfy most water demands, as long as it is adequately treated to ensure water quality appropriate for the use. In uses where there is a higher possibility of human exposure to the water, more treatment is thus required. As for any water source that is not properly treated, health problems can easily arise as a result of exposure to recycled water which might contains disease-causing organisms or other contaminants.

We therefore employ the latest innovations and technologies and apply a tailor-made philosophy on each project starting from the design phase until the project is handed-over to the customer whether we are dealing with the construction of a new plant or the refurbishment and upgrade of an existing plant.

Depending on the type of water medium and the size of the plant, a combination of the following methods can be applied:

- Physical, chemical and mechanical pre-treatment

- Biological aerobic activated sludge processes with nutrients removal and sludge regeneration

- Membrane bioreactor filtration technology for high levels of purification

- Biological anaerobic processes for high efficiency and low space requirements

- Anaerobic sludge treatment for the generation of biogas and energy

- Physical, chemical and mechanical sludge thickening and dewatering

- Physical, chemical and mechanical treatment of effluent water for polishing and reuse applications

For decentralized solutions, we offer compact sewage and grey water treatment plants that are ideal for single houses or a small group of housing units. These systems work with the Membrane Bioreactor (MBR) filtration process which is characterized by:

- High levels of purification making the treated water reusable (fit for unrestricted irrigation, toilet flushing and cleaning). The water reuse dramatically reduces the drinking water consumption

- No chlorination or any disinfection required since the treated effluent is free of germs, bacteria and viruses

- Minimal maintenance and energy requirements

- Compact installation

- Part of the cost for these systems is subsidized by the water authorities

- In the wastewater treatment sector MEKEL has applied several processes ranging from traditional activated sludge processes to more recent Membrane Bioreactor (MBR), Moving Bed Biological Reactor (MBBR) and Integrated Fixed-film Activated Sludge (IFAS).

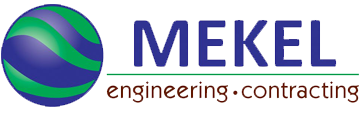

Membrane bioreactor (MBR) is the combination of a membrane process like microfiltration or ultrafiltration with a suspended growth bioreactor widely used for municipal and industrial wastewater treatments. The MBR processes use the membrane as a filter, rejecting the solid materials which are developed by the biological process, resulting in a clarified and disinfected product effluent. This provides a number of advantages relating to process control, product water quality and low footprint requirements. The filters are submerged in the mixed liquor and clean permeate is drawn through the membranes using a slight negative pressure. The tiny pores of the membranes physically block particles, bacteria and viruses creating permeate of exceptionally high quality.

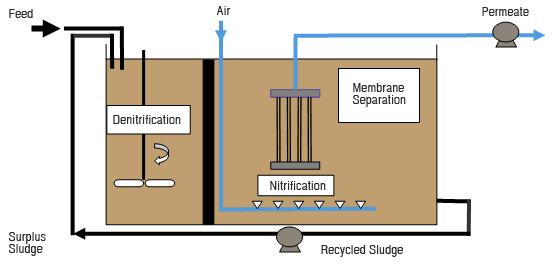

The MBBR (Moving Bed Biological Reactor) technology is a simple, single-through process, where all biological activity takes place on the biomass carriers. This process prevents sludge recycle from a secondary clarifier. MBBR technology is robust and reduces soluble pollutants with minimal process complexity. MBBR solutions also utilize a significantly smaller physical footprint compared to conventional aerobic treatment methods. MBBR is typically used for either high load industrial applications, as stand-alone or as a buffer stage, as well as for robust simple-to-operate municipal facilities.

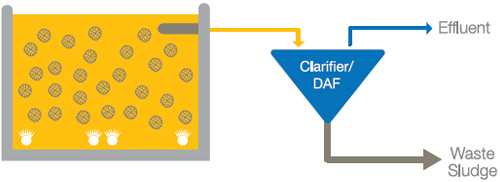

The IFAS (Integrated Fixed-film Activated Sludge) process combines conventional activated sludge technology and biofilm systems into a single reactor. In general an IFAS configuration is similar to an activated sludge plant, with biomass carriers utilized in specific stages of the process. This creates a synergy between two distinct biological processes: the MLSS degrades most of the organic load (BOD), and the biofilm creates a strong nitrifying population for oxidation of the nitrogenous load. IFAS is typically used to upgrade existing plants to enhance nitrogen removal, or in the design of new plants to enable extensive BOD and nitrogen removal.

Solid Waste Management

Design and Construction of Technical Projects in the environmental sector. Top quality and certified equipment. Operation and maintenance of works.

- Collection Garbage skips (Κάδοι Διαλογής)

- Underground systems (Συστήματα Υπόγειων κάδων)

- Compactors (Συμπιεστές)

- Garbage Chutes (Συστήματα Αγωγών Απορριμμάτων)